5040 of Water-based Rust Inhibitor

This product has excellent spreading performance, relying on the anti-rust function of surfactant molecules quickly combined with metal molecules to form a protection, to avoid direct metal and air direct contact with the oxidation reaction, so as to achieve the purpose of long-term anti-rust. After the product is processed, it does not need to be cleaned before entering the next process, which has no effect on the product size and surface finish, and does not affect the subsequent welding, pasting and other properties.

Classification:

Key words:

industrial rust inhibitor

Product Description

Water-based Rust Inhibitor QR-5040QX

Product Introduction:

Water-based Rust Inhibitor is independently developed by our company and is made of the latest water-based raw materials. It does not contain carcinogenic substances such as nitrite and is widely used in steel, castings, alloy steel, ductile iron, auto parts and other rusty materials. Its environmental protection, odorless, non-volatile, less residue, safety and other properties are the best choice for replacing anti-rust oil.

Usage:

Cleaning, Cleaning, Floating Water, Floating Water, 2-4% Concentration Rust Inhibitor, Drying Thousands.

Note: In case of flash rust (rust starts to appear in the floating water link), 1-2% QR-5040QX water-based rust inhibitor can be added to the floating water tank.

Scope of application:

is widely used in steel parts, metal processing parts, castings, forgings, cylinder liners, crankshafts, bearings, ferrous metals in the manufacturing and maintenance of water pump machinery, auto parts and many other industries. Rust, semi-finished products and finished products.

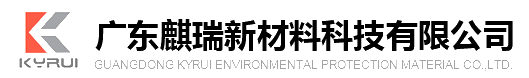

1. product principle:

This product has excellent spreading performance. It relies on surfactant molecules with anti-rust function to quickly combine with metal molecules to form protection, so as to avoid direct metal oxidation reaction in direct contact with air, thus achieving the purpose of long-term anti-rust. After the product is processed, it does not need to be cleaned before entering the next process, which has no effect on the product size and surface finish, and does not affect the subsequent welding, pasting and other properties.

2. Product Features:

| Item | Indicator | Test Method |

| Appearance | Light Yellow Transparent Liquid | Visual Observation |

| PH | 8.5-10 | PH Extensive Test Paper |

| Antirust Performance | 2-3 months | hanging film test |

rust prevention period is different due to the difference of ambient temperature, humidity and corrosive components, usually up to 90 days, cast iron carbon steel type easy to rust material 30 days.

3. application scope:

, used for oil-free short-term rust prevention (inter-process rust prevention) of rust-prone metal workpieces such as cast iron and steel parts, and suitable for short-and medium-term rust prevention treatment of ferrous metal materials and parts in the overhaul process of various machinery and equipment of industrial production enterprises.

2, used for electroplating, phosphorus chemical parts passivation anti-rust treatment, can greatly improve the corrosion resistance of electroplating layer, phosphating film. Preparation and use conditions of

5. antirust working fluid:

ratio (dilution weight ratio of stock solution mixed with water):2-5% concentration, I .e. 1 part of this product: 20-50 parts of water (depending on antirust requirements)

antirust period: 2-3 months temperature: normal temperature -50 ℃ (normal temperature can be used, in order to make the anti-rust workpiece dry quickly, the anti-rust liquid can be heated to 40-50 ℃) soaking time: 2-3 minutes

6. precautions:

. In general, the workpiece can be immersed in the working liquid for 2-3 minutes to achieve satisfactory anti-rust effect. If large and complex workpieces are treated by spraying (brushing), it should be ensured that the liquid fully wets all corners of the workpiece, and uneven treatment will seriously affect the anti-rust effect.

2. Before anti-rust treatment, it is necessary to ensure that the surface of the workpiece is free of oil pollutants, rust and granular attachments. The higher the surface finish, the better the anti-rust effect. Do not bring acidic water into the anti-rust liquid, otherwise the anti-rust liquid will fail and the anti-rust effect will be poor. After the workpiece is derusted with acid, rinse at least two times with flowing water to ensure that the surface of the workpiece is neutral.

3. Under normal circumstances, the concentration of anti-rust working fluid will not decrease, but the quantity should be reduced. Add stock solution and clear water in proportion. When the rust inhibitor is brought into the tap water or cleaning agent residue, the pollution can not effectively prevent rust, you need to re slot. Recommendations and cleaning agent slotting time is roughly the same.

4. For workpieces treated with antirust liquid, it is best to blow off the residual moisture on the surface and each dead corner with a spray gun connected with compressed air, and then dry them. If possible, it is best to dry them. The dried workpieces should be placed on the ground based on dry packing boxes or wood boards.

5. Before preparing the working solution, shake the barrel several times before pouring out the stock solution.

7. packaging and storage:

25kg/barrel, sealed and stored in a cool and ventilated warehouse with a shelf life of two years.

8. customer group:

The company's direct or indirect customers include: AVIC, BYD, Jinlong Bus, Bosch, Valeo, Dongfeng Motor and other dozens of well-known enterprises.

Previous Page

Previous Page

Next Page

Related Products

online message