Copper oxidation resistance CU269

The use of this product through immersion treatment, the copper surface to form a layer of dense single-molecule protective film, can effectively isolate the air and copper surface contact, so as to prevent corrosion discoloration;

Classification:

Key words:

industrial rust inhibitor

Product Description

JY269 Copper Passivator

1. Features of this product:

. After soaking treatment, a dense single-molecule protective film is formed on the copper surface, which can effectively isolate the contact between air and copper surface, thus preventing corrosion and discoloration.

2. This product does not contain toxic and harmful substances such as chromate, fluoride, peroxide, heavy metal, etc., and has no three waste discharge problems, therefore, it has no pollution to the environment and is an environment-friendly product.

3, does not affect the electroplating efficiency and welding performance of the workpiece, has no effect on the conductivity, and can eliminate this protective film by dipping in weak acid;

4, can effectively prevent copper discoloration and markings, and is not easy to leave watermark after soaking, and can maintain the original luster of copper products;

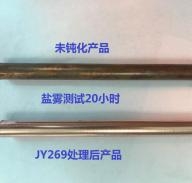

5. The protective film produced after treatment can pass the salt spray (NSS) test for more than 20 hours.

2. Scope of application:

Applicable material: brass, copper, copper alloy, copper plating, beryllium copper and other copper products.

III. Physical Indicators:

|

Features Exterior (stock solution) Appearance (diluent) Odor Pour Point Density PH (5%) |

Unit ■ ■ ■ [℃] [kg/m. 15 ℃] ■ |

data transparent yellowish liquid transparent liquid no 2 1008 8.5±0.5 |

processing area: each kg of protective agent can treat 10-20 square meters of copper (according to the actual situation)

IV. Usage:

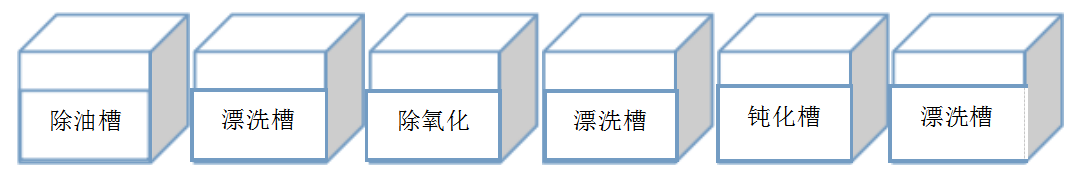

Copper protection treatment: JY-269 diluent → floating water → drying

) Usage ratio depends on the required protection time, however, the company's JY-269 concentrated solution can be diluted 10-30 times for use)

2) temperature: 25 ℃ -40°C

3) treatment time: 60-180 seconds

4) stirring: uniform mechanical stirring

5) working equipment: storage equipment for stainless steel, glass, polypropylene, polyethylene and other materials

6) replacement of new liquid: when the water film breaks on the surface of the workpiece and the solution is contaminated, need to be newly equipped with protective liquid

Note: The workpiece must be cleaned during operation, and metal ions such as copper and iron must not be brought into the working liquid, otherwise the effect will be reduced. In addition, the workpiece after copper protection treatment, not bare hands contact, so as to avoid hand sweat pollution rust.

5. packaging specifications and transportation:

plastic barrel packaging 25kg/barrel, according to the general chemical transportation, light loading and light unloading, to prevent heavy pressure inversion. Store in a ventilated place at room temperature. Shelf life two years

Previous Page

Next Page

Previous Page

Next Page

Related Products

online message